AyrKing

DrumRoll

The DrumRoll Automatic Breading Machine automates the breading process for fried foods, reducing the need for skilled labor while ensuring consistent, high-quality coatings. Using a patented helix-shaped component, the DrumRoll gently tumbles products for an even breading that minimizes “blow-off” in the fryer, extending the life of both fryer oil and breading.

Operators simply load chicken or other proteins into the DrumRoll through a loading chute, and the machine’s tumbling action evenly coats the product before it exits down an unloading ramp into a feathering basket. Compared to manual breading, the DrumRoll uses 13% less breading, 5% less fryer oil, and achieves 32% greater consistency, with production time improved by 25%.

Options for Every Workflow

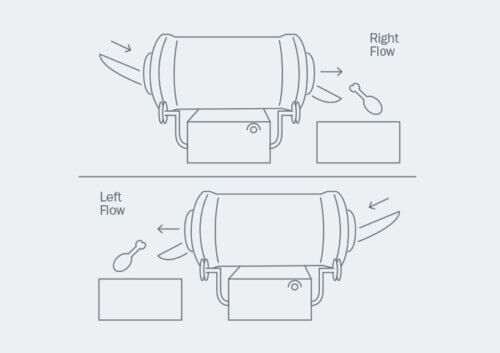

The DrumRoll Automatic Breading Machine offers flexible workflow options to fit any kitchen setup. Choose from a “right flow” (left-to-right) or “left flow” (right-to-left) configuration to align with your workspace needs. For added versatility, the “UF” DrumRoll model allows on-site adjustments, enabling you to easily switch flow directions as needed.

Two Convenient Sizes

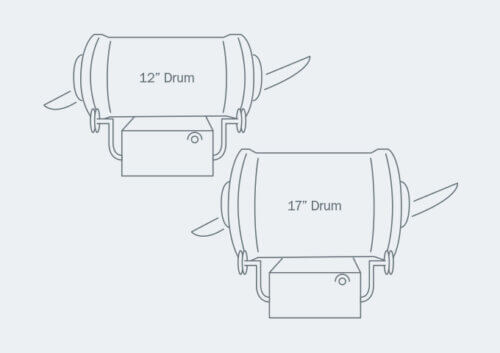

The DrumRoll Automatic Breading Machine is available in two vessel sizes to suit different volume needs. The Mini DrumRoll features a compact 12-inch diameter vessel, ideal for smaller kitchens or lower volume requirements.

For higher volume operations, the standard DrumRoll comes with a larger 17-inch diameter vessel, providing ample space for breading larger quantities with ease. This model also includes a magnet opening, which simplifies the dumping and containment of flour, keeping the workspace clean and reducing flour waste.

Endless Possibilities

The BBS and DrumRoll machines are engineered to seamlessly integrate, offering versatile configurations to meet a wide range of breading and workflow needs. Whether optimizing for workflow direction, vessel size, or specific options like cold storage and tailored brush and screen settings, these machines can be combined to enhance efficiency and consistency in any kitchen.

By pairing the BBS’s streamlined breading prep process with the DrumRoll’s automated breading capabilities, operators can create a setup that minimizes labor, extends product shelf life, and maximizes breading and oil usage. HP Sales Northeast is available to guide you through the best configuration for your kitchen’s exact needs, helping you design a breading station that supports volume demands, available space, and desired breading consistency. Contact us for expert recommendations and to create a custom solution tailored specifically to your operation.

View Videos

Key Features

- Automated Breading Process – Fully automates breading, reducing the need for skilled labor and delivering consistent results.

- Helix-Shaped Tumbling Mechanism – Uses a patented helix design to tumble and coat products evenly, minimizing breading “blow-off” in the fryer, which extends the life of both breading and fryer oil.

- Customizable Workflow Options – Available in “right flow” and “left flow” configurations, with an “UF” option for on-site directional adjustments to fit any kitchen layout.

- Two Vessel Sizes – Offered in 12-inch (Mini) and 17-inch (Standard) vessel sizes to accommodate different volume needs, with a magnet opening in the standard model for easy flour dumping and containment.

- Improved Efficiency – Provides 32% greater consistency, uses 13% less breading, and achieves a 25% faster production time compared to hand breading, helping reduce ingredient waste and increase productivity.

Product Gallery

View Product Info

schedule your kitchen demo today

Come in and take the recipe challenge in our test kitchen. We’ll demo our equipment, help you improve your existing approach, and find what equipment works for you.