In the fast-paced world of commercial kitchens, maintaining top-notch food quality is crucial. Henny Penny’s blog, “3 Ways Commercial Fryers Help Restaurants Maintain Food Quality,” outlines three key ways in which commercial fryers play a vital role in achieving this goal.

Precise Temperature Control:

Commercial fryers are masters of temperature precision. They ensure that oil remains at the perfect temperature, guaranteeing consistent cooking results. This accuracy means your fried foods come out crispy and golden every time, delighting customers with their taste and appearance.

Fast Recovery Time:

When the kitchen gets busy, every second counts. Commercial fryers boast rapid recovery times, swiftly returning the oil to the desired cooking temperature after food is submerged. This quick turnaround ensures that your dishes are cooked evenly and retain their delicious flavors, even during the busiest rushes.

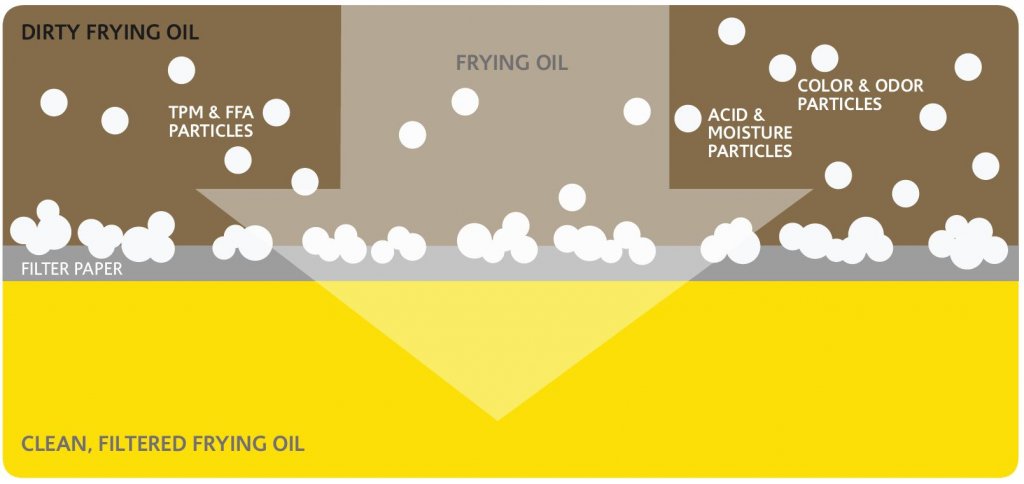

Oil Filtration and Management:

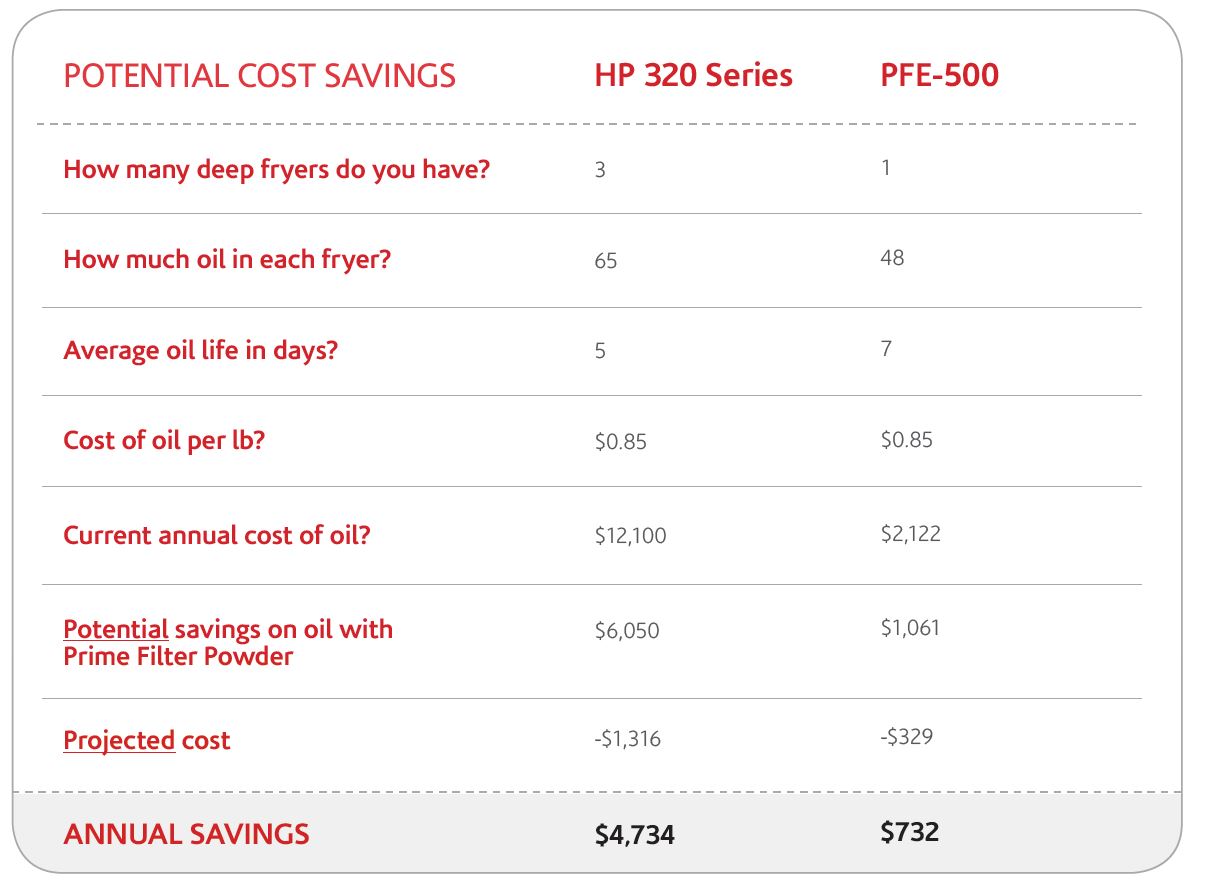

Depending on what type of cooking oil you purchase, a JIB will now run you as much as four times what you paid in 2019. So, today you’ll pay between $40 and $100 for a JIB of cooking oil and that’s wholesale pricing.

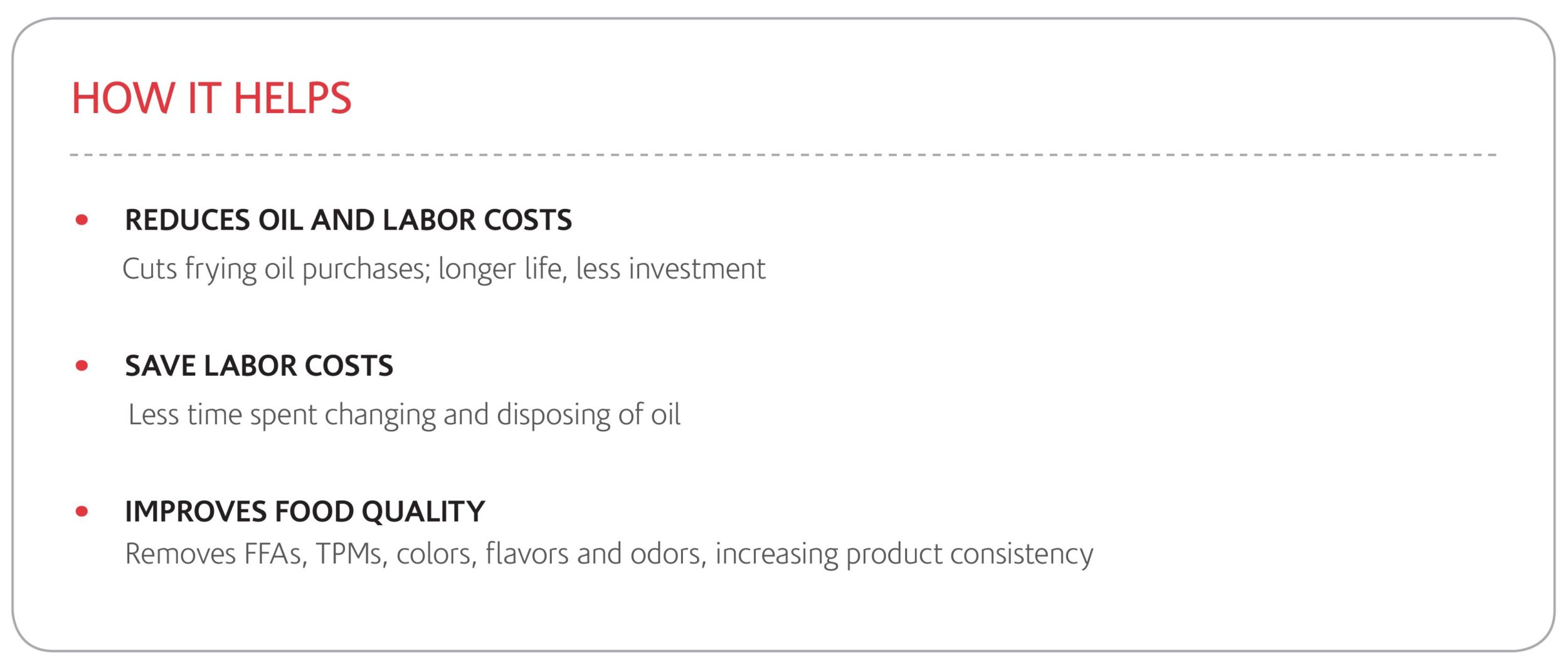

High-quality fryers take oil management seriously. They come equipped with features like automatic filtration, which extends the life of the cooking oil and reduces waste. By efficiently removing debris and maintaining oil quality, these fryers contribute to consistent food taste and texture while also saving costs. This free Filter Frequency Calculator will help you determine the ideal filtration frequency for your restaurant. Additionally, Henny Penny’s Prime Cleaner product is a game-changer when it comes to extending your oil life.

“Our owners have 21-year-old fry pots looking like they’re brand new. Plus, they’re saving time on each clean-out, since you don’t need to neutralize with a vinegar solution.”

In summary, commercial fryers are culinary workhorses that contribute significantly to maintaining food quality in bustling restaurant kitchens. Their precise temperature control, fast recovery times, and effective oil management make them indispensable tools for ensuring that every dish served is consistently delicious and satisfying.

Want some tips on how to refine your frying program? This free download includes the top five frying mistakes and what you can do about them.