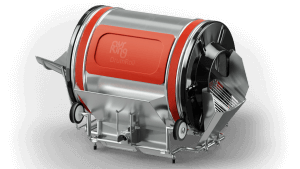

The AyrKing Breader Blender Sifter (BBS) is a nifty piece of equipment, if we do say so ourselves. Not only can incorporating a BBS into your kitchen extend the life of your ingredients and cut waste, it can also reduce hand-sifting time by 80%. If your staff spends 20 hours a week sifting, that’s 16 hours back!

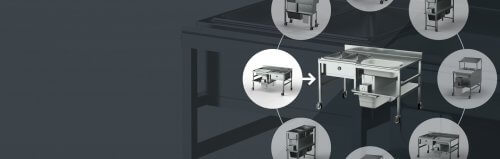

Choosing a BBS for your operation is a no-brainer, but with so many different options, configurations and add-ons, how can you select the perfect combination for your very specific needs?

We don’t believe in a one-size-fits-all piece of equipment. When thinking about how to best tailor a BBS to fit your operation’s individual needs, there are several important factors to evaluate first.

Think through your kitchen’s details

We offer so many different BBS models and bundles because we realize no two kitchens are exactly the same. Although you might have other kitchen factors you’ll want to keep in mind, the big three to consider are

- operation type

- available space

- workflow.

Consideration #1: Operation type

From bustling high-volume takeout restaurants to sit down dining in a limited-size venue, the type and quantity of food you serve at your foodservice operation is the first consideration. How much will you use your BBS and for how many different selections?

- If you specialize in hand-battered fried food, you’ll need to produce large amounts of consistent product. Consider purchasing a BBS unit and a DrumRoll Automated Breader to allow the volume turnover your operation requires.

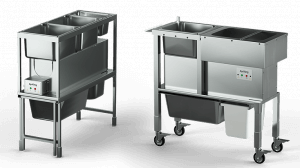

Consideration #2: Available space

Commercial kitchen plans are rarely standardized, and many face space limitations of varying degrees for both width or depth. Think about which might be more of a limiting factor when selecting the proper model.

Most standard BBS models start at 29 inches in width, but we also offer some options for those who need a smaller footprint.

- If your kitchen has less than 14 inches of width available, for example, the BBS Thin will be a good fit for workflow in a narrow space.

- If you have more than 35 inches of width in your workspace but are limited in depth, the smaller footprint of the BBS Mini would be an ideal model to consider.

Consideration #3: Workflow

When contemplating workflow and how it might impact your BBS model decision, think about whether your breading area is directional from left-to-right or right-to-left, as well as what sort of variability you encounter in your menu selections and staff needs.

- The BBS Ice model, for example, has flexibility for both flow options — right-to-left or left-to-right — to adjust for any application. It combines a standard BBS model with a cold prep table for keeping proteins within arm’s reach.

- The BBS Flex can help fit any workflow, especially if yours is ever-changing or needs to be reconfigured from time to time. In just seconds, the BBS Flex can be adjusted to fit a range of employee heights or workflow direction.

Think through your production details

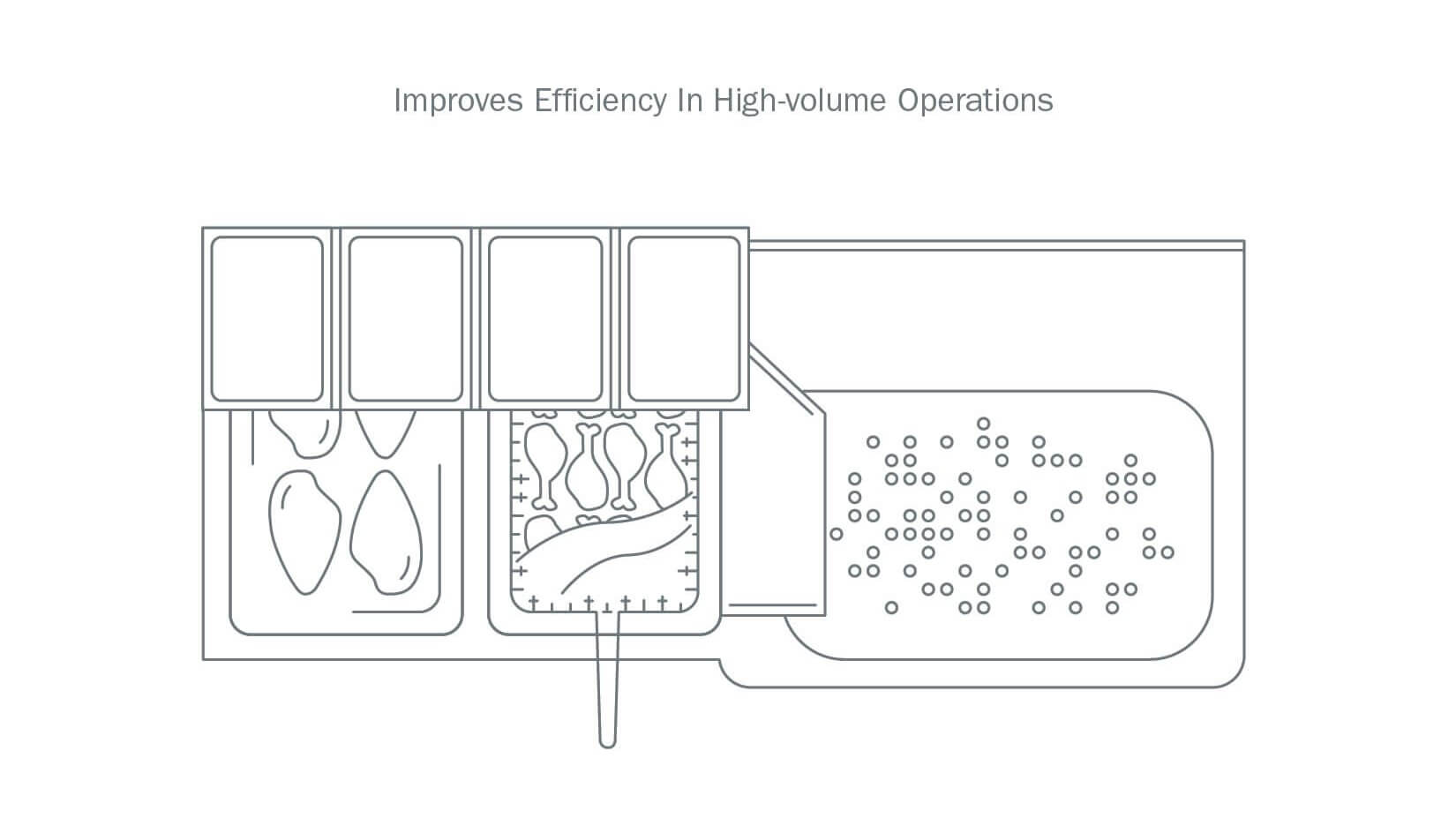

In addition to the unique physical factors of your commercial kitchen layout, it’s equally important to understand your production details to choose the ideal BBS model for your operation. We’ll need to weigh several factors, including what types of proteins you serve and how they are breaded, as well as production volumes and types of breading utilized.

Consideration #4: Ways in which proteins are breaded

Chefs realize there are many different ways to prepare a protein for frying. Some choose to pre-marinate a protein, while others use a wet batter followed by dry breading. Whether a protein is bone-in or boneless will also have an impact on the coating process workflow.

- To simplify the marination process, consider adding on a commercial marinating machine.

Consideration #5: Volume of production

The amount of breaded product produced and sold daily will influence the ideal BBS model for your operation. But where is the line between a moderate and high volume?

- If you’re processing 50-100 pounds of product per day, whether protein or otherwise, we recommend you check out the BBS Mini.

Consideration #6: Types of breading

The type of breading that is used in your recipes can play a significant role in selecting the best BBS model for your operation.

Dry breading varies in the flour-to-spice ratio, and your menu may offer more than one flavor profile as well. Wet breading, or a combination of water batter and dry breading, will also influence the best model for you.

- If you’re using more than one flavor profile, you might want to consider the BBSU8132 for your needs. This model offers you an 81-inch-wide work area with two sifters for the best efficiency with multiple breading flavors.

- Wet breading that is milk- or egg-based will require an Ice Bath with your BBS to ensure your wet ingredients stay at the proper holding temperatures. You can explore the BBS Ice model or even add an Ice Bath onto another BBS model, depending on your needs.

- If you use water and dry breading, models like the BBSUL2934BPC have the perfect configuration with a sifter and back panel.

While it’s true there is a lot to consider when deciding on the ideal BBS model for your foodservice operation, thoroughly reviewing each of these six considerations will ensure you are maximizing your efficiency while reducing costly waste, in both staff time and ingredients.

Even better, we have a tool that will help you get a head start on the research process! Check out our BBS product selection guide to help you narrow down the models that are right for you!

AyrKing is a Trusted Partner with Some of the Biggest Chains Around