It’s harder than it looks, but we make it easy.

Ever wondered how your favorite restaurants manage to serve piping hot and delicious meals even during the busiest hours? Dive into the fascinating world of food holding with Henny Penny’s latest blog post, “The Science Behind Holding Cabinets.”

Discover the secrets that top chefs and foodservice professionals rely on to maintain food quality, flavor, and temperature. From the principles of heat transfer to the art of holding cabinets, we’ll unravel the science that ensures your meals are always served at their best.

Join us on this culinary journey as we explore the behind-the-scenes magic that keeps your dining experience exceptional.

Originally posted on www.HennyPenny.com

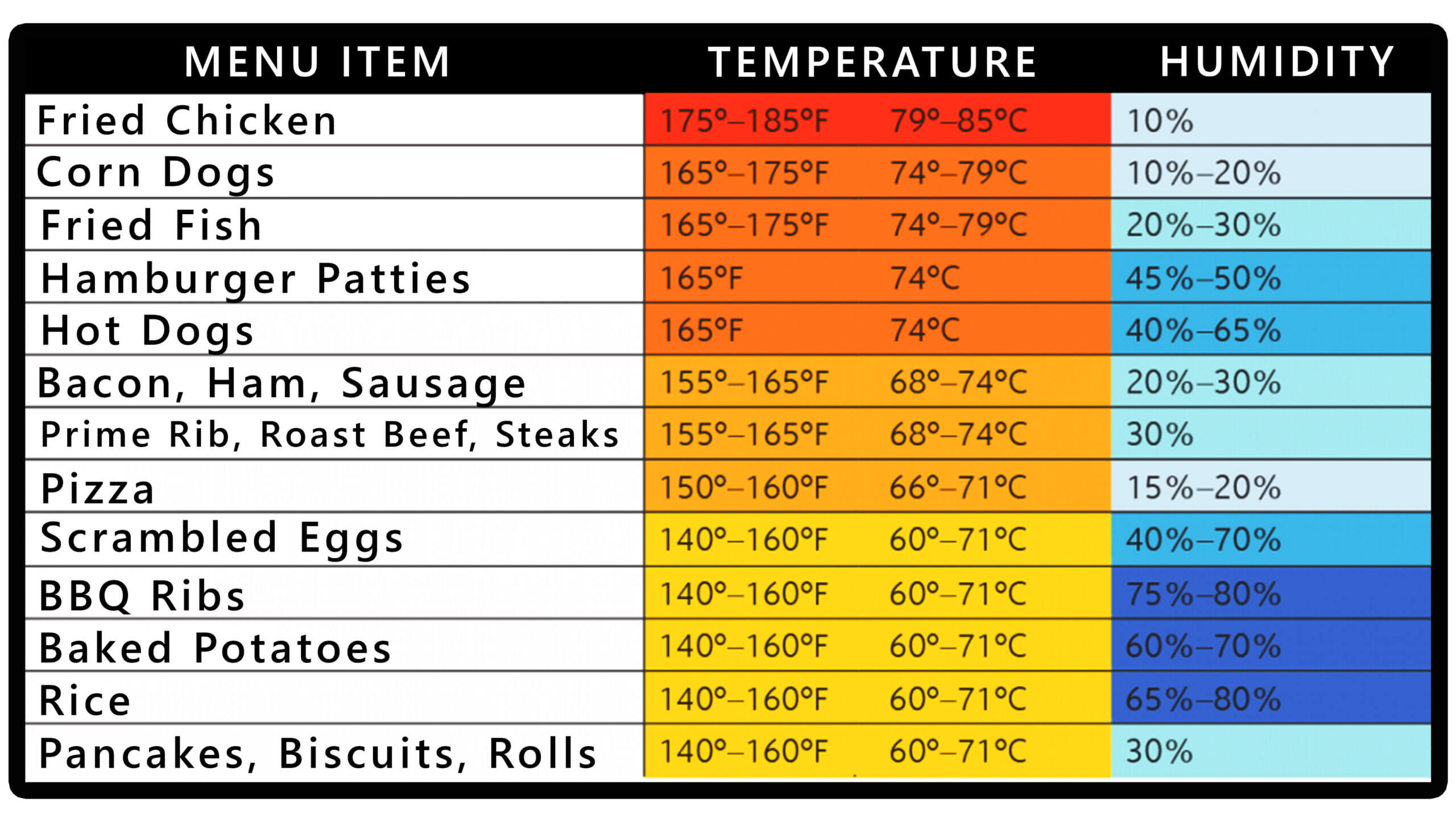

“The below chart shows popular menu items grouped by common holding temperature ranges.* Items in the same temperature range can generally be held together. Holding times will vary depending on the durability of the item and humidity in the cabinet. The Humidity column shows ideal relative humidity. With a controlled humidity holding cabinet, much longer holding times can be achieved.”

“The Science Behind Holding” – Henny Penny

*Based on Henny Penny HHC 900 and SmartHold cabinets. Results will vary for other manufacturers.