The restaurant industry is reeling from a widely reported labor shortage, causing many operations to change the way they function.

Some fast food chains have resisted opening their dining rooms, kept shorter operating hours and placed high demands on existing employees in order to function with a smaller staff.

The reasons for the shortage, which is affecting restaurants from quick serve to fine dining, are complex and hotly debated. But whether the root cause is higher unemployment benefits, an industry for low wages and difficult working conditions, or the pandemic and its chilling effect on the hospitality industry as a whole, the result is that restaurants are put in a position of doing more with less. The root cause of the issue could be multifaceted, involving higher unemployment benefits, the industry’s historic reputation for low wages and challenging working conditions, or the pandemic’s impact on the hospitality sector. Regardless, the outcome is that restaurants now face the challenge of having to operate with fewer resources.

The Challenge

Lower-than-desired staff levels can have a ripple effect on a restaurant’s operation.

In full-service restaurants, fewer front-of-house workers means larger sections for each worker to cover, potentially resulting in slowed or worsened service as servers rush from table to table.

In every kind of operation, fewer back-of-house workers to prepare meals means longer wait times for orders to be fulfilled and a potential increase in errors from rushed workers.

The end result may be less efficiency and thus less revenue — not to mention unhappy customers.

To adapt to these challenges, many restaurants have cut their hours — eliminating a meal period like lunch or an entire day of service — reduced their seating capacity, or shrunk their menu to streamline kitchen operations.

The Solutions

The solutions to this industrywide challenge are multi-layered, and operators are working both ends toward the middle. They’re focusing not only on improving staffing levels but also on adjusting processes to boost efficiency and throughput.

On the staffing side, restaurants can seek to improve hiring through creative (and generous) hiring tactics. A focus on retaining existing workers by boosting morale and creating a positive work environment can also have a lasting impact.

On the other end of the equation, operations are seeking to reduce the number of employees needed to run a restaurant.

This is the approach favored by Beef O’Brady’s, a 176-unit full-service chain that is looking at options like menu items that require less prep, technologies that allow customers to order and cash out at their tables, and more efficient back-of-house equipment in order to run its restaurants with fewer workers.

In fact, equipment changes can have a surprisingly large impact on labor needs. Automating labor-intensive processes frees personnel up to perform other tasks and reduces the labor hours needed to churn out meals.

Enter Ayr King

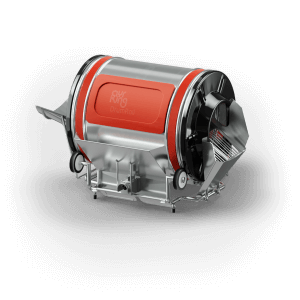

AyrKing’s DrumRoll Automated Breader is one such option that enables restaurants to produce the same amount of freshly breaded fried foods with less labor.

Fresh breading is typically a labor-intensive process. But the unique spinning helix design of the DrumRoll quickly and efficiently breads proteins and vegetables, reducing labor and accelerating production by an average of 25%. It takes just one minute to bread 60 wings or 40 seconds to bread eight pieces of chicken.

In addition, the DrumRoll is ideal for kitchens where there are often new and inexperienced workers because there’s very little training involved — as opposed to hand breading, which requires solid training and experience to achieve consistent results.

The DrumRoll Automated Breader also improves product consistency by more than 30% over traditional hand breading, providing a better customer experience.

Pair the AyrKing DrumRoll with our Breader Blender Sifter for even more efficiency. The BBS cuts hand-sifting time by 80% and extends the life of breading mixtures, reducing waste and cutting costs.