3 Tips on Employee Retention from Restaurant Industry Experts

As COVID-19 restrictions on indoor dining ease, restaurants are celebrating the return of customers to their establishments. However, a new obstacle has emerged in the form of the ‘Great Resignation.’ While diners are coming back, restaurant operators are struggling to fill positions with sufficient staff. Read “How to Attract and Retain Kitchen Staff During The Great Resignation” from Henny Penny’s blog for the full scoop.

The ‘Great Resignation’ phenomenon gained momentum in late 2021, when a record breaking 4.5 million Americans quit their jobs. And, in February 2022, another 4.4 million Americans quit their jobs. This has left the industry grappling with a labor shortage crisis. The Foodservice Industry, which saw almost 7 percent of America’s food and beverage workforce walk off the job, left nearly a million job vacancies. Restaurant operators are now in a race to recruit new hires.

Where did they go?

Many restaurant employees who were displaced during the pandemic have opted to pursue more stable and better-paying opportunities in different sectors, and rightfully so. Investing in their future is one of the best things an employee can do. However, this heightened demand for restaurant workers has created a significant challenge for operators.

“This is something the industry’s never seen before, but it’s been building up for a while. COVID was just the tipping point. People who had dedicated their lives to restaurants, me included, found themselves unemployed when the restaurants they were working for closed. So, out of necessity, they had to pivot, and many found other jobs that were more stable and paid better.”

Chef Gregg Brickman

Corporate Executive Chef at Henny PennySo how do we keep employees around?

To entice and retain staff, restaurants are offering competitive wages, sign-on bonuses, flexible scheduling, and, in some cases, condensed workweeks. Beyond financial incentives, operators are recognizing the importance of showing appreciation and acknowledgment to their employees.

Companies like HOA Brands and McDonald’s are demonstrating their commitment to workers by investing in them, providing referral programs, and offering training and development opportunities to support their success.

Working smarter, not harder.

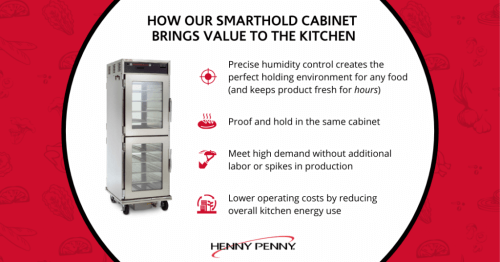

In addition to wage incentives and appreciation, simplifying job tasks is proving essential. Restaurants are adopting user-friendly equipment designed to reduce arduous and time-consuming chores. This not only eases the burden on employees but also contributes to smoother operations.

Streamlining training processes is another crucial aspect of improving the employee experience. Many restaurants provide on-site training, visual guides, video tutorials, and 24/7 assistance to ensure employees feel confident in their roles.

While automation and robotics are making their way into the restaurant industry, they are seen as complements rather than replacements for human workers. The personal touch and warmth of human interactions remain irreplaceable.

A brighter future.

In summary, the ‘Great Resignation’ presents a significant challenge to the restaurant industry. However, by offering competitive compensation, simplifying job tasks, valuing and appreciating employees, and providing comprehensive training, operators can navigate this turbulent period and ensure the industry continues to thrive.

Read the full blog over at HennyPenny.com