Most operators don’t set out to buy cheap equipment. They buy it because opening costs pile up fast, cash flow is tight, and saving a few thousand dollars feels responsible in the moment. But the real commercial fryer operating cost shows up later in labor pressure, recovery speed, oil life, and downtime risk.

We’ve seen this play out hundreds of times. Sometimes cheaper equipment, or even used equipment, works fine for a while. Then real volume hits, staffing gets tight, and small performance differences turn into daily problems. The real test of equipment is not install day. It is Friday at 6 pm.

Here is where cheap equipment usually costs operators the most.

How Recovery Time Impacts Commercial Fryer Operating Cost (And Your Reputation)

Recovery time is its own problem because it hits customer wait times and service flow immediately.

When a fryer cannot recover temperature quickly between drops, the kitchen starts falling behind orders. Ticket times stretch. Drive-thru times increase. Guests start noticing inconsistency or longer waits, especially during peak periods.

At that point, equipment performance stops being a back-of-house problem and becomes a customer satisfaction problem. Sometimes it becomes a reputation problem. Faster recovery helps kitchens stay ahead of orders instead of constantly chasing them. You see it in speed of service, repeat visits, and how stressful peak hours feel for your team.

Oil Life: The Daily Cost Most Kitchens Underestimate

In heavy frying operations, oil life is a HUGE expense.

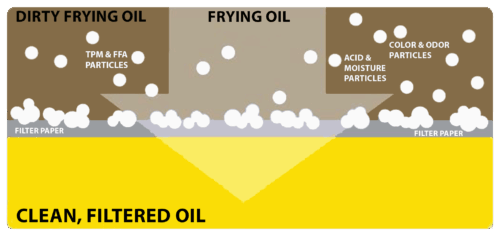

Non-filtering or poorly designed systems can force operators into changing oil far more often just to hold product quality. In some cases, that can mean daily oil changes, which creates a massive ongoing cost.

Henny Penny fryers protect oil by holding temperature more consistently and making filtration easy enough that staff actually follow the process during a real shift. When filtration is built into the workflow instead of feeling like extra work, oil life improves fast.

Over a year, oil cost differences alone can outweigh the entire savings of buying lower cost equipment upfront. Many operators see Henny Penny fryers pay for themselves in the first couple years once oil savings are factored in.

Downtime And Service Reality: Where Cheap Gets Very Expensive

Downtime is where the difference between equipment providers becomes obvious very quickly.

As a Henny Penny distributor, we’re required to have technicians on the road in fully stocked service vehicles. If something goes wrong, response is fast and most repairs get done right the first visit.

Lower tier equipment often does not have that support structure. Parts can be difficult to source, which stretches downtime. Operators often end up calling whoever is available locally instead of trained specialists. That usually means longer diagnosis time, repeat failures, and more disruption inside the kitchen.

When core cooking equipment fails during peak hours, you do not just lose product. You lose momentum, staff confidence, and sometimes customers who do not come back.

The Used Equipment Trap We See Over And Over

There is another version of this that shows up all the time, and it is not just cheap new equipment. It is used equipment.

We regularly see operators buy a used fryer thinking they are saving money, only to spend months chasing reliability. By the time they replace worn parts, pay labor to diagnose unknown issues, and deal with repeated downtime, they often spend as much or more than a new unit would have cost.

On top of that, they usually do not get warranty protection, structured startup, or proper staff training. That means the kitchen is learning the equipment the hard way, during live service, instead of starting with a clean baseline and support behind it.

Used equipment can make sense in very specific situations, but most operators underestimate how much risk they are taking on. When core cooking equipment is unreliable, it does not just cost money. It costs stability, and stability is what allows kitchens to grow.

The Operators Who Stop Buying Based Only On Price

The most experienced operators shift their thinking away from purchase price and toward operational stability. They start asking different questions.

- How fast can this recover during peak volume?

- How easy is it for staff to filter correctly every time?

- If this fails, who is fixing it and how fast can they respond?

Those questions usually lead to better long term equipment decisions.

If You’re Tired Of Fighting Your Equipment, There Is A Better Way

If you are serious about long term frying performance, it is worth seeing what operators get from Henny Penny fryers in real kitchen conditions. Recovery speed, oil protection, and consistency are why so many high volume kitchens rely on them every day.

When you look at real commercial fryer operating cost over time, performance and service support matter far more than purchase price.