The restaurant industry has had its fair share of challenges in recent years. The pandemic took aim at struggles that owners and operators were already facing: labor shortages and the rising cost of food and oil. Many now need a way to make up for these losses, and prioritizing food quality and consistency is a great place to start. The Henny Penny F5 fryer is here to help.

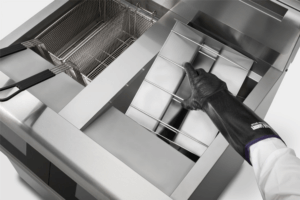

Henny Penny’s new low oil volume F5 fryer is here for foodservice operators looking to save money on oil and take the worry out of frying.

New and improved features transform back-of-house frying operations and offer a simpler way to focus on what really matters: your guests.