Rising Costs, Labor Shortages, and How Henny Penny Can Help.

Restaurants are still feeling the squeeze of foodservice inflation, supply chain delays, and labor shortages. Rising ingredient costs and the struggle to meet demand with fewer staff are forcing owners to do more with less every day.

While 2024 showed promising signs of slowdown, food cost is still an everyday headache. If you’re in this industry, you’ve probably felt the pinch in some way.

But here’s the thing: While you can’t control inflation or predict when supply chain issues will ease, you can control how efficiently your kitchen operates. One key move? Upgrading to equipment designed to save you money on energy, oil, and labor. That’s where Henny Penny comes in.

The Inflation Rollercoaster: More Than Just Food Costs

Foodservice inflation isn’t just about the skyrocketing prices of ingredients anymore. Utility bills are up, maintenance costs are higher, and with ongoing supply chain bottlenecks, it’s taking longer and costing more to get crucial equipment. It’s like a double whammy—restaurants are spending more on less, while also waiting longer for basic supplies.

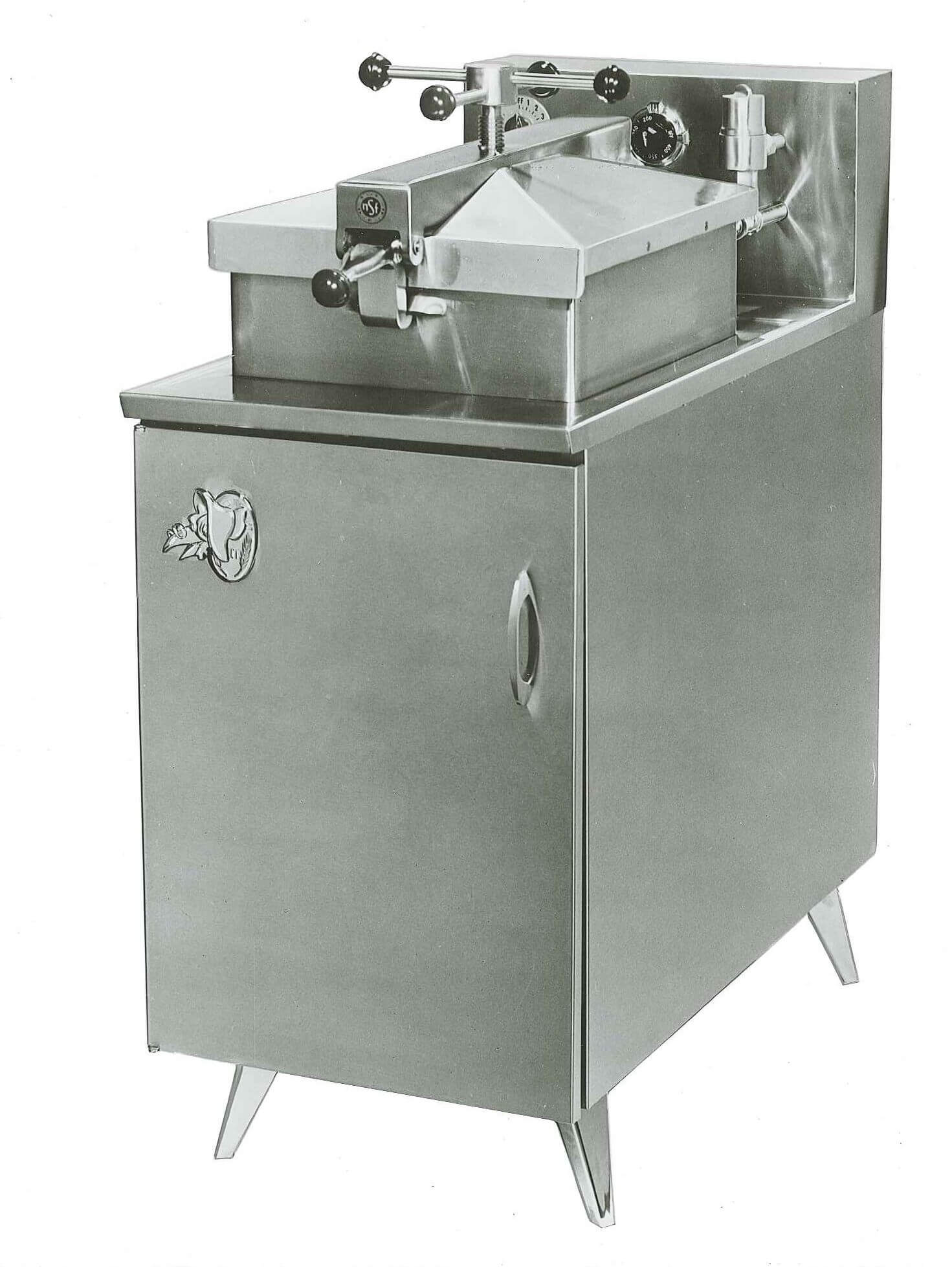

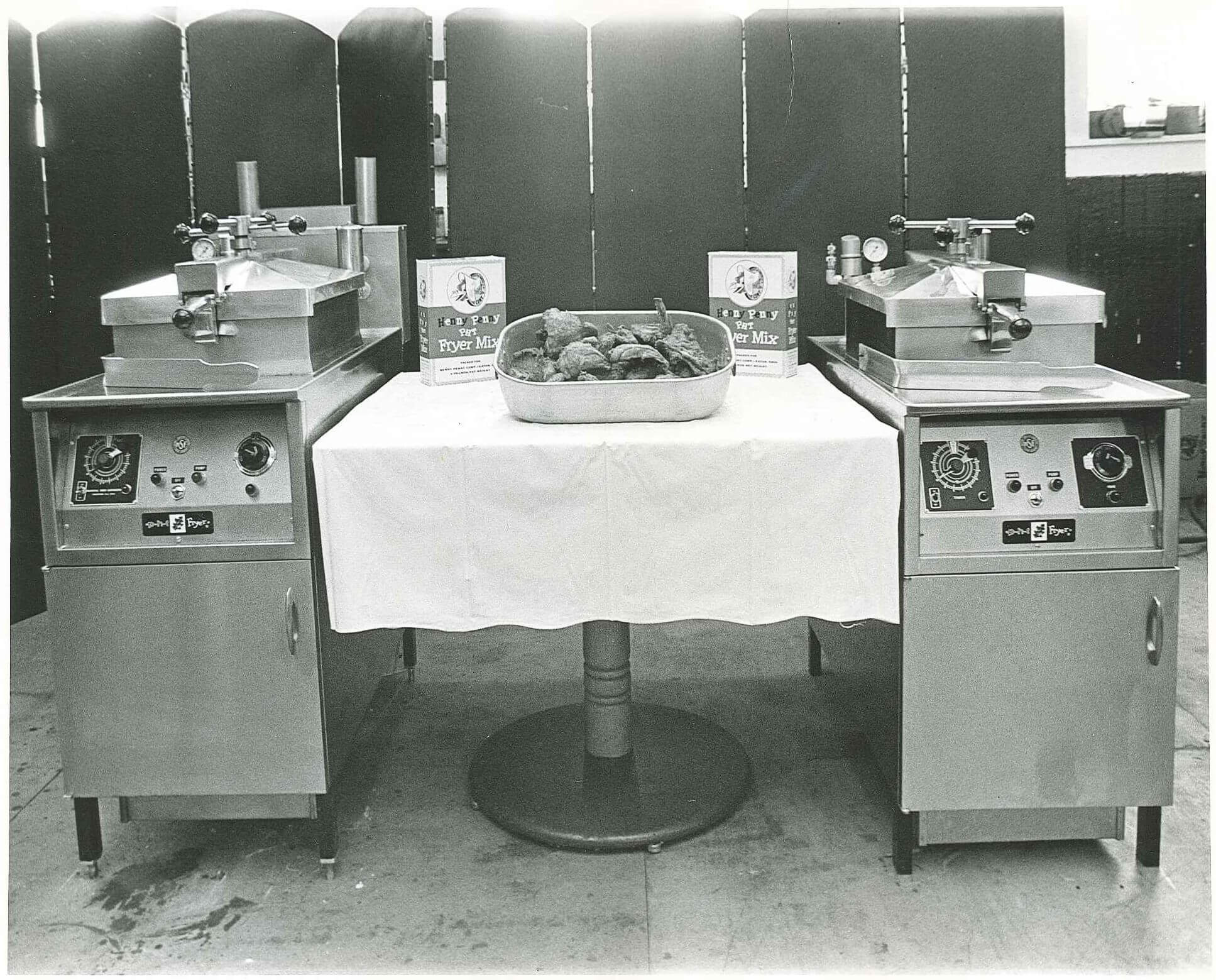

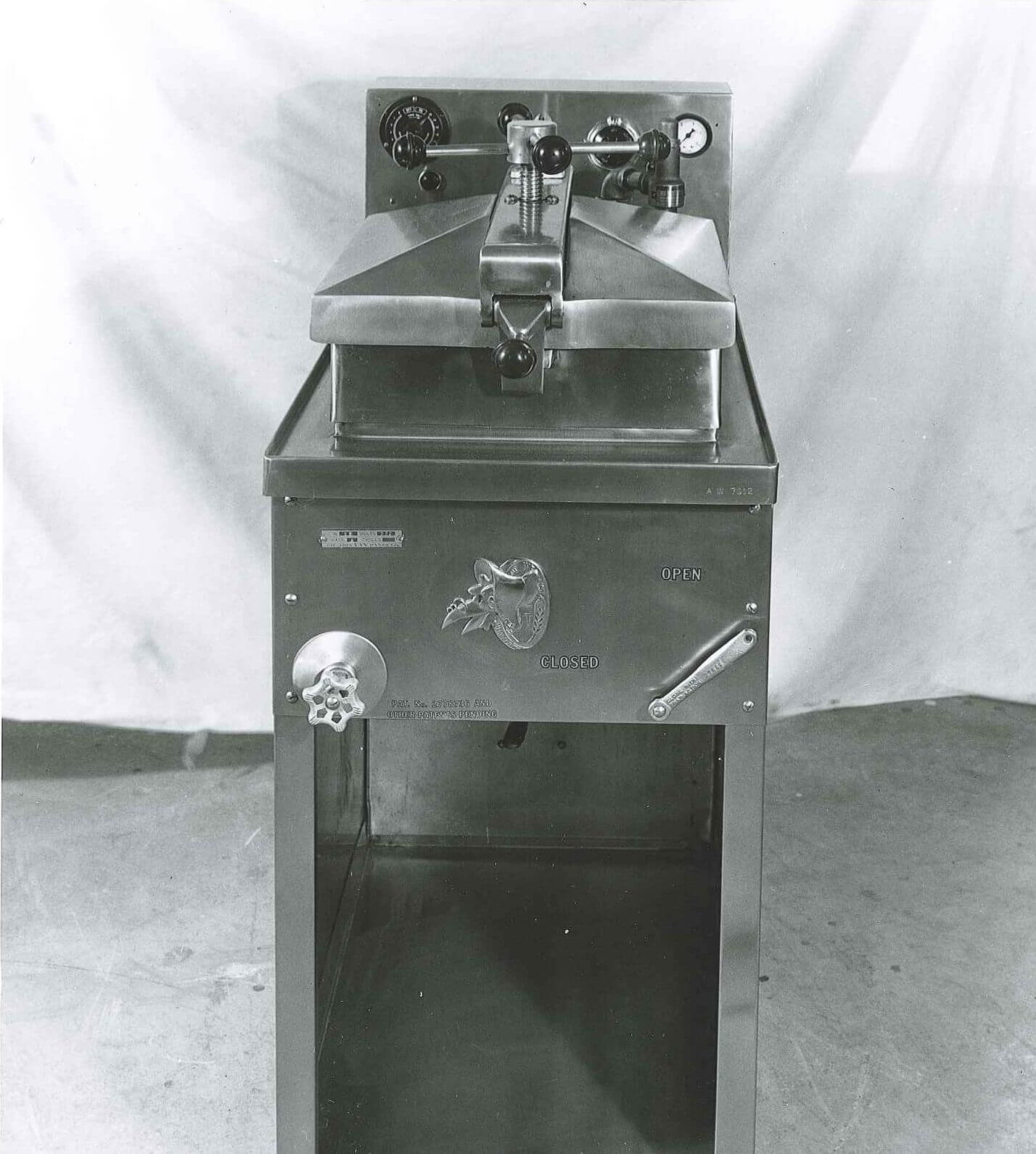

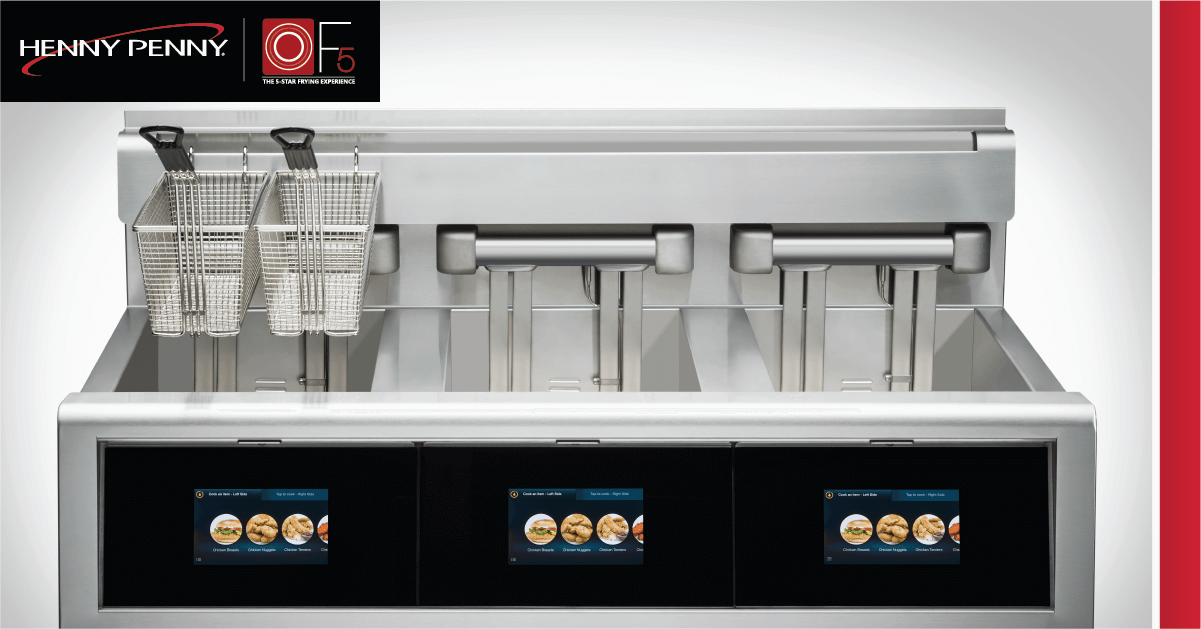

With this kind of pressure, squeezing every bit of efficiency out of your kitchen is essential. Henny Penny fryers and holding cabinets can help you reduce your energy consumption, which can take the sting out of those increasing utility bills. Their energy-efficient designs use less power while maintaining top performance.

Stretching Your Oil Further

Speaking of rising costs, we all know how the price of oil has jumped. This is where Henny Penny fryers truly shine. Their innovative oil-saving technology ensures that you’re using oil more efficiently—meaning you buy less of it over time. If you’re frying all day long, the savings really start to add up. In fact, some operators have reported cutting their oil usage nearly in half. Run the numbers to see for yourself.

You can’t stop foodservice inflation, but reducing oil waste? That’s one thing you can control. See how we helped a regional fried chicken chain save on oil costs here.

Labor Shortage? Let the Equipment Do the Heavy Lifting

Let’s not forget the staffing challenges. Hiring and retaining kitchen staff has been a nightmare for many restaurants over the last few years, with more employees leaving the industry and fewer people looking to get into it. We’ve talked before about how difficult it is to keep staff in this climate, but now the focus has to be on making things easier for the employees you do have.

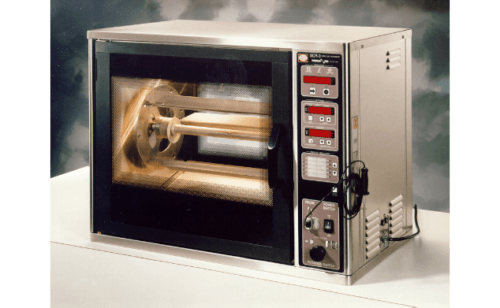

This is where the right equipment can make a world of difference. Henny Penny fryers and combi ovens feature designs that minimize the need for constant monitoring. They’re easy to use, enabling fewer staff to handle more tasks in the kitchen, so you can keep up with demand even when running a lean crew.

The Solution is Smarter, Not Harder

You don’t have control over foodservice inflation or supply chain problems, but you do have control over your kitchen’s efficiency. Investing in reliable, oil- and energy-saving equipment like Henny Penny fryers can help mitigate some of the pain that comes with rising costs and a shrinking workforce. In a time when everyone’s looking for ways to save, this might just be the edge you need.

When it comes to taking your foodservice establishment to new heights, Henny Penny products and HP Sales Northeast are the winning combination. From unmatched support and flexibility to cost savings and confidence in quality, this partnership offers a comprehensive solution for culinary success.

Don’t settle for anything less – help us elevate your foodservice experience today.