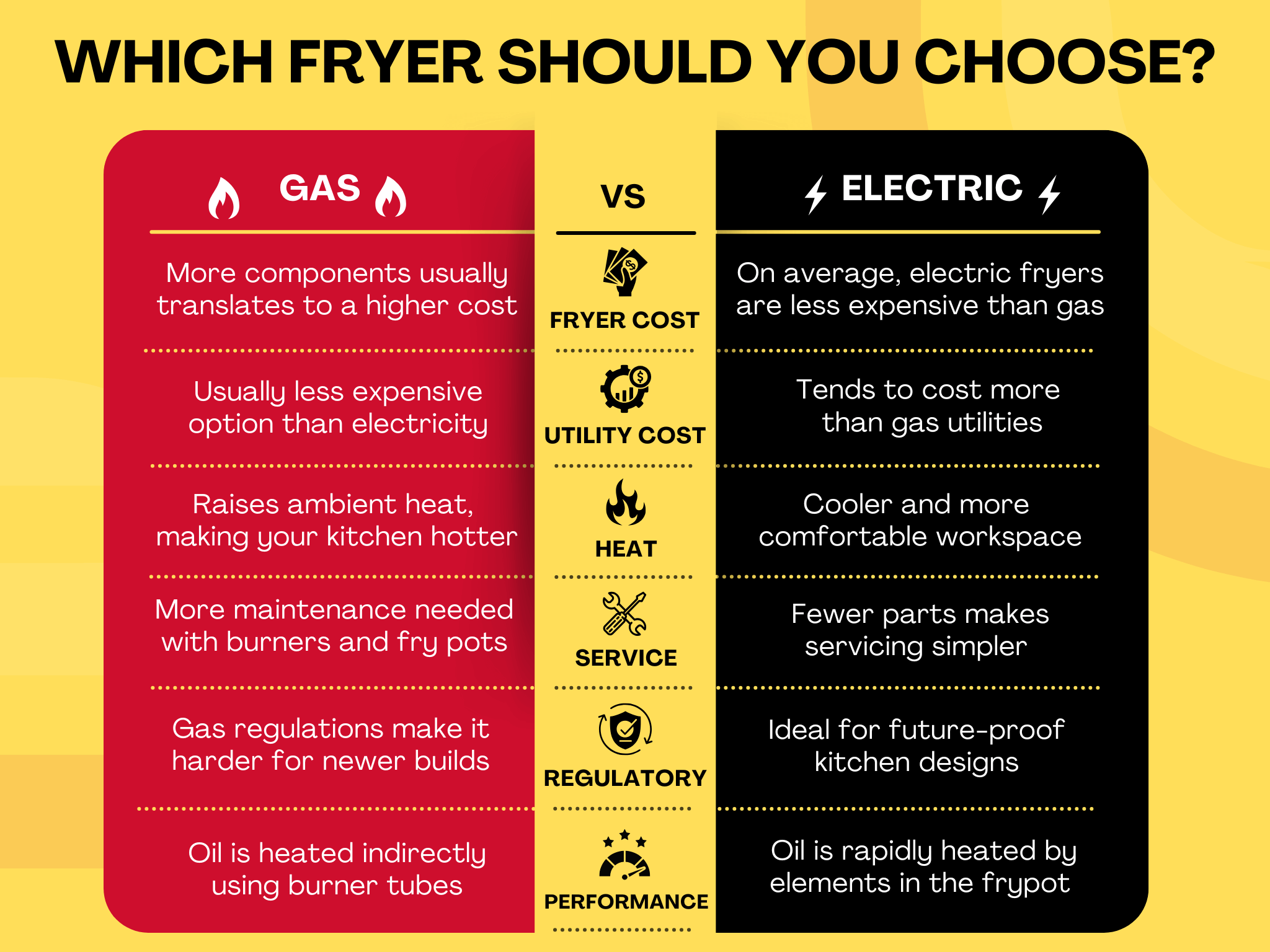

Choosing between a gas and electric fryer isn’t just about what’s cheaper to run. There are lot’s of things to factor in, like how it affects your maintenance costs and whether your new equipment will pass inspection. If you’re planning a remodel or opening a new location, this decision matters more than ever. Almost every Henny Penny demo touches on gas vs electric fryers for this same reason.

As cities tighten restrictions on gas in new kitchens and manufacturers prioritize electric, more operators are asking the same thing: what should we buy next? If you’re opening a new spot or upgrading your line, now’s the time to rethink how you power your fryer.

Why Choose Electric Fryers?

The first thing you want to look at is price, I get it. Well, there’s two things to consider here.

- When comparing an electric fryer to its gas counterpart, they’re usually less expensive. Without burner tubes or gas lines, electric units cost less to build. More on this below.

- Electricity as a utility is, on average, more expensive than gas.

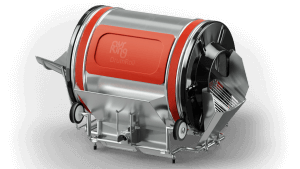

Electric fryers heat oil by sending power directly to elements sitting inside the vat, as seen in the photo above. No flame or no burner tubes; just direct, even heat. Electric fryers plug in and go. No gas hookup, no special permitting, and they’re easier to relocate if you ever change your layout. That’s a big deal in new builds or tight kitchens.

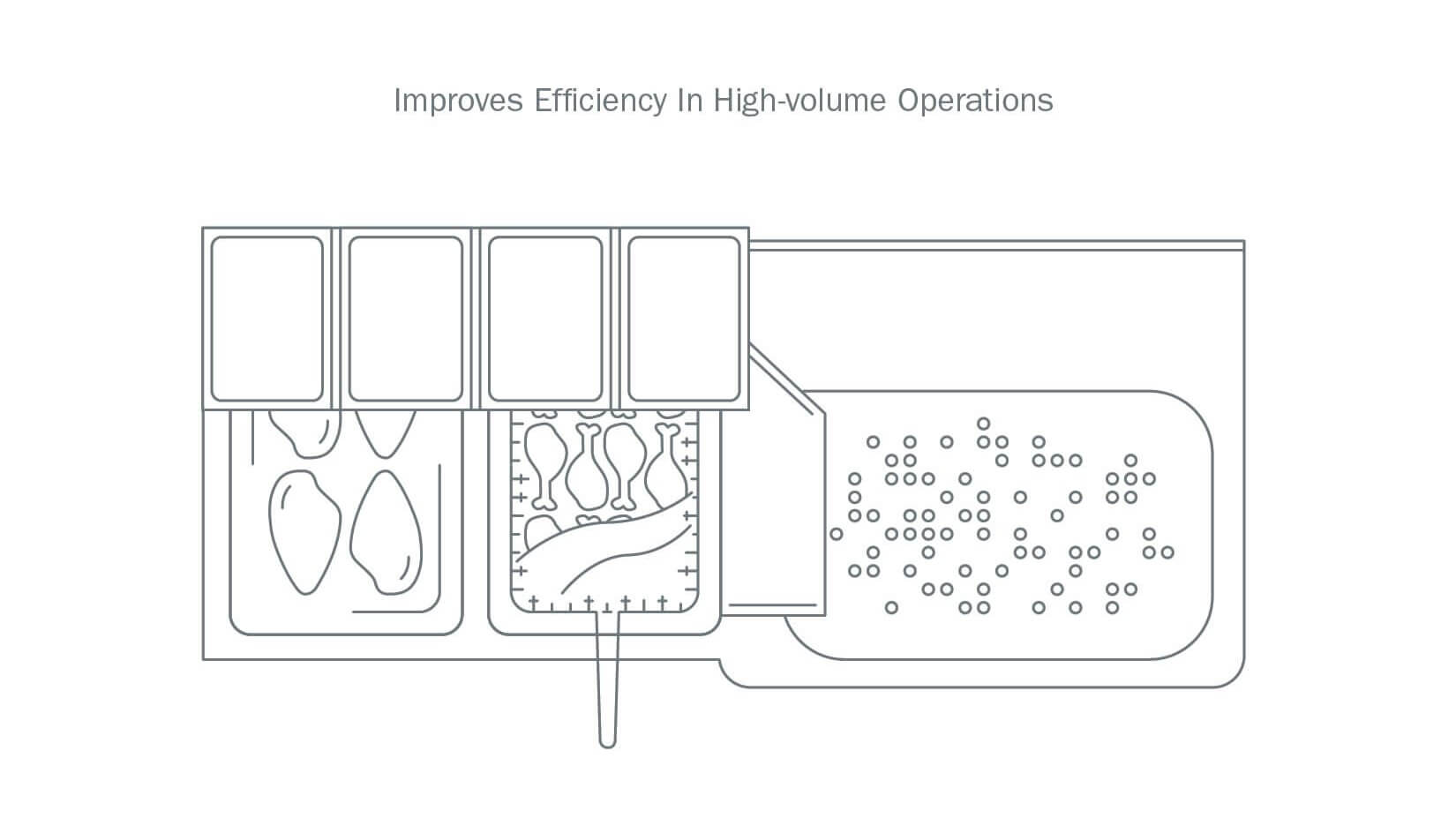

They also keep your kitchen cooler. Since they don’t rely on open flame, there’s less ambient heat pouring out around the fryer. That’s better for your staff and your air conditioning bill. Temperature control is precise too. When you drop frozen chicken, it recovers fast without spiking.

And yes, Chick-fil-A runs electric across the board. They’re not guessing. They did the math.

Easier to Service

It’s a cleaner design with fewer moving parts under the hood, which makes installation and service a whole lot easier. If you’ve ever waited days for a gas valve replacement, you know how much that matters.

Government Restrictions

More and more cities are starting to restrict gas hookups altogether. If you’re building or expanding, you might not even have the option. That’s part of why newer Henny Penny models like the F5 and the Velocity launched as electric only. It’s not a trend, it’s the direction the industry is heading.

Why Choose Gas Fryers?

Gas fryers use flame to heat burner tubes that warm the vat, which heats the oil. It’s a more complex chain reaction, but it works. If you’ve got a high-volume kitchen and already have gas service in place, it may be the cheaper route with your utility bill.

I’m sure by now you can sense a theme around cost. While gas equipment is cheaper to run, it might end up costing you more money somewhere else down the line. The cost of the fryer itself is normally more expensive and back of house HVAC isn’t cheap.

Natural gas, depending on your market, is usually less expensive than electricity. If you’re slamming out back-to-back batches all day long, that savings adds up. While gas itself usually costs less per BTU than electricity, especially if your rates are favorable, it throws off more ambient heat. That means your kitchen gets warmer, and your HVAC has to work harder.

If your staff has been using gas forever, there might be a comfort level with the setup. But you’re trading that for more heat in the kitchen, more complex components, and the possibility for more frequent service calls.

You also have to factor in where the regulations are going. A gas fryer that works today might not be allowed in a remodel five years from now.

So What’s the Move?

If you’re building new or willing to upgrade your lines, electric is probably the smart choice. Easier to install, easier to work on, and less likely to run into permitting headaches. It’s also where manufacturers like Henny Penny are putting their focus. The features, the R&D, the new launches—all electric first.

Gas still works. If you’ve got the infrastructure and you’re running nonstop, it might make sense to stick with it for now. But don’t get stuck in “we’ve always done it this way” mode. That mindset has cost operators more money than they realize.

Electric isn’t just a plan B anymore. It’s often the better option up front.