Are you looking to ramp up efficiency in your commercial kitchen without expanding your team? You’re in luck! Henny Penny’s article, “Why Your Commercial Kitchen Needs A Pressure Fryer And Heated Holding Cabinet,” offers some game-changing insights. Let’s unpack the key points.

The Dynamic Duo: Pressure Fryers and Holding Cabinets

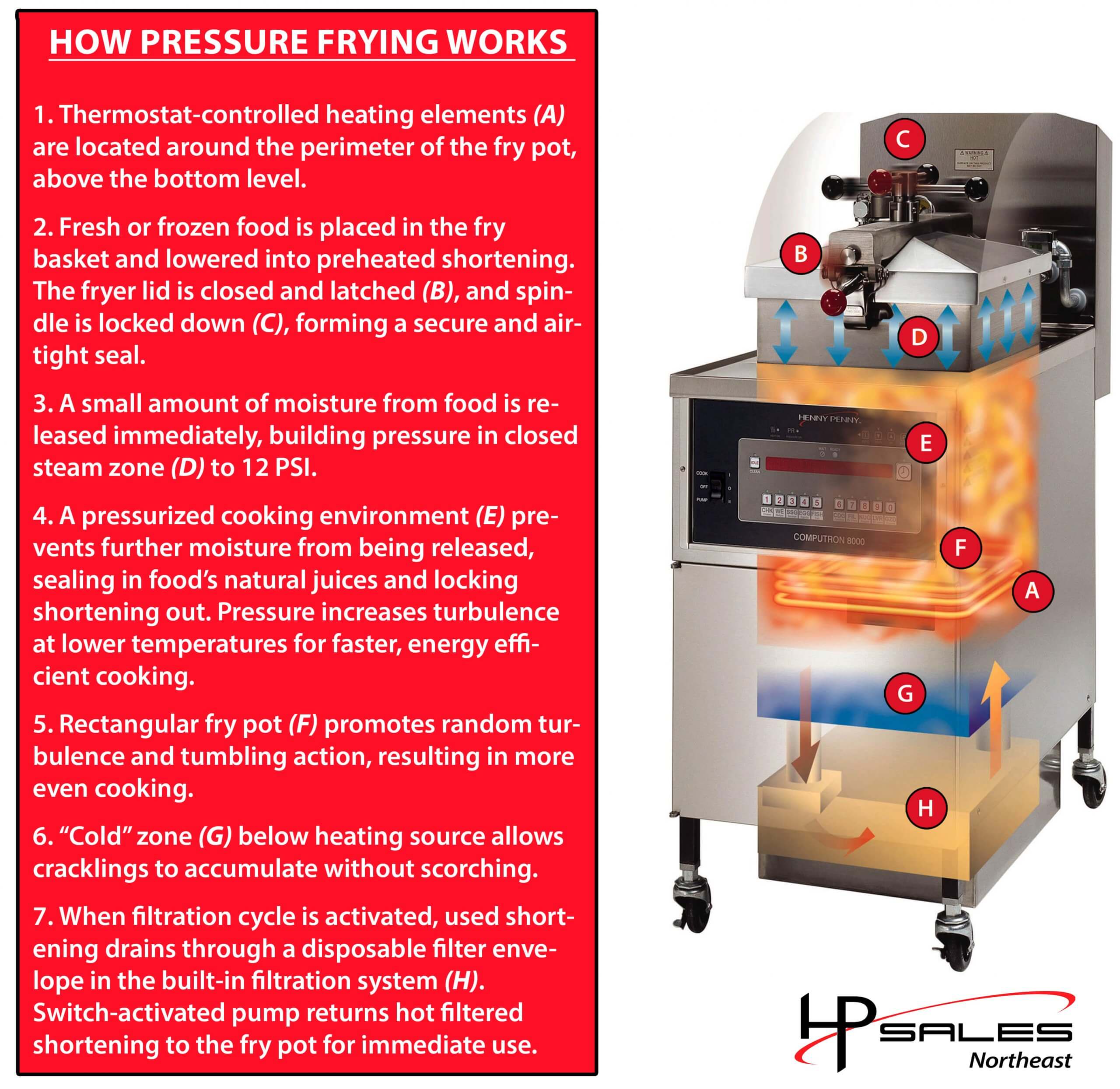

This article spotlights a dynamic kitchen combo: pressure fryers and heated holding cabinets. Why this pairing? Well, pressure fryers excel in locking in moisture and flavor of fried chicken, making them an essential piece for any high-volume kitchen. They cook quickly, maintain quality, and seal out excess oil.

But that’s just half the story! Heated holding cabinets enter the scene to keep that freshly fried chicken perfect for hours. They’re not just warming boxes; they’re sophisticated pieces of equipment that maintain temperature and moisture, ensuring your chicken stays fresh, juicy, and ready-to-serve.

Less Staff, More Efficiency

One of the biggest wins? This combo allows for batch cooking. You fry a bunch of chicken in advance and then keep it ready in the holding cabinets. This means during rush hours, you’re not scrambling. Instead, you’re efficiently serving up delicious, hot chicken.

Boost Throughput, Reduce Waste

Batch cooking isn’t just about efficiency; it’s about smart management. It helps increase throughput, especially important when balancing dine-in and delivery orders. Plus, it significantly reduces food waste – a crucial factor in today’s eco-conscious world.

Pressure Fryers and Holding Cabinets; A Perfect Match

At Henny Penny, pressure fryers and holding cabinets are designed to work seamlessly together. This integration means better food quality, increased safety, and a smoother process for your staff. Incorporating a pressure fryer and heated holding cabinet into your commercial kitchen is more than an upgrade – it’s a strategic move towards operational excellence. Want to dive deeper? Check out the full article for a comprehensive understanding of this potent kitchen duo.

Check out our Fried Chicken Restaurant Equipment Guide to read more about the equipment you’ll need to start dishing out golden-fried goodness.

Originally posted on HennyPenny.com