For quick service restaurants (QSRs), managing frying oil is crucial for maintaining food quality, operational efficiency, and profitability. Yet, many operators underestimate the importance of regularly filtering their frying oil. Neglecting this simple maintenance task can lead to poor food quality, increased costs, and even safety hazards. This guide breaks down why filtering your frying oil is vital for a successful foodservice operation, how it impacts your commercial equipment, and what you can gain from proper oil management.

1. The Impact of Clean Oil on Taste and Quality

Keep Your Customers Happy with Great Tasting Food

Your customers notice when food tastes great, and clean frying oil is a huge part of that. Unfiltered oil accumulates particles that can alter the flavor of your fried foods, leading to off-tastes that drive customers away. Regular filtration helps keep the oil fresh, resulting in better-tasting, consistent products that keep patrons coming back.

2. Economic Benefits of Regular Oil Filtration

Save Money by Extending Oil Life

Many foodservice operators think frequent oil changes are their only option for maintaining quality. In reality, regular filtration can significantly extend the life of your oil. This means fewer oil purchases, lower disposal costs, and ultimately more money saved for your business.

Filtration also improves the efficiency of your equipment, leading to reduced energy consumption. Cleaner oil heats more evenly, which translates into lower utility bills and a smoother kitchen operation.

3. Reduce Equipment Wear and Tear

Protect Your Investment in Commercial Equipment

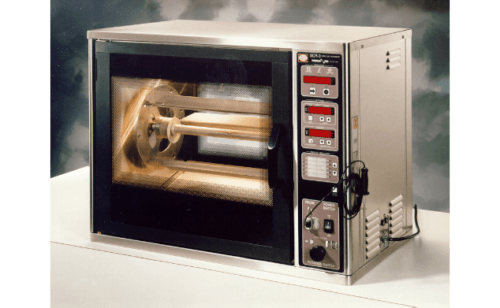

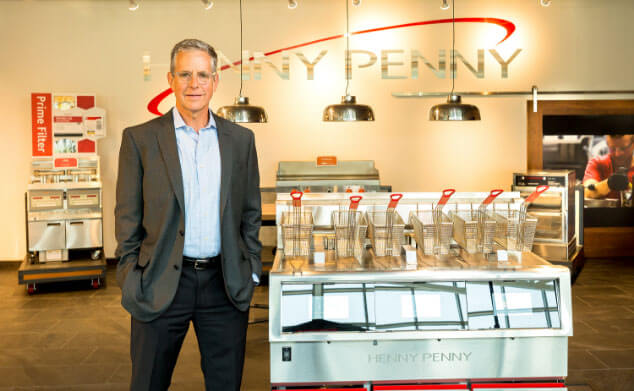

Your commercial fryers are a major investment, and protecting them should be a priority. Using unfiltered oil can clog fryers with debris, leading to breakdowns and expensive repairs. At HP Sales Northeast, our factory-trained technicians often see the damage caused by poor oil management. Unlike third-party service providers who may need multiple visits and manufacturer guidance, our techs arrive fully stocked with parts, ensuring a quick fix when you need it most.

4. Enhancing Safety in Your Kitchen

Avoid Hazards with Clean, Well-Maintained Oil

Keeping oil clean isn’t just about quality; it’s also about safety. Dirty oil is more likely to cause dangerous splattering, which can result in burns and slips. Degraded oil also produces more smoke, potentially irritating the eyes and lungs of kitchen staff. By maintaining clean oil through regular filtration, you reduce these risks and create a safer environment for your team.

Regularly filtering your oil can prevent these issues, creating a safer work environment for your employees. At HP Sales Northeast, we emphasize proactive maintenance to help our clients avoid these risks, saving them time and potential liability costs.

5. Environmental Benefits of Oil Filtration

Reduce Waste and Your Carbon Footprint

In today’s market, sustainability is more than just a trend—it’s a priority for many customers. Regular filtration means less frequent oil disposal, reducing waste and your restaurant’s environmental footprint. Fewer oil changes mean less packaging, fewer deliveries, and a smaller carbon footprint overall. It’s a simple change that benefits your bottom line and the planet.

6. Improve Customer Satisfaction and Reputation

Quality Fried Food Keeps Customers Coming Back

The quality of your fried foods directly affects customer satisfaction and your restaurant’s reputation. Clean oil means consistent quality, leading to positive reviews and repeat business. On the other hand, unfiltered oil can result in lower food quality and negative word-of-mouth. For a QSR, maintaining a strong reputation through great-tasting food is essential, and clean frying oil is a key part of that equation.

Ultimately, the goal of any foodservice business is to satisfy customers. Clean oil leads to consistently good-tasting fried foods, which means happier customers and better reviews. Positive word-of-mouth can be a powerful driver for new business, especially in a competitive market like QSRs.

Make the Most of Your Frying Oil

Filtering your frying oil regularly is a small step that yields big benefits for your QSR. From improving food quality to extending the life of your commercial equipment, the advantages are clear. With HP Sales Northeast’s expertise and service support, you can ensure your kitchen operates efficiently, safely, and profitably.

Ready to elevate your frying operations? Reach out to HP Sales Northeast today to learn more about how our service department can keep your kitchen running smoothly, saving you money and improving your customer experience.

Do The Math

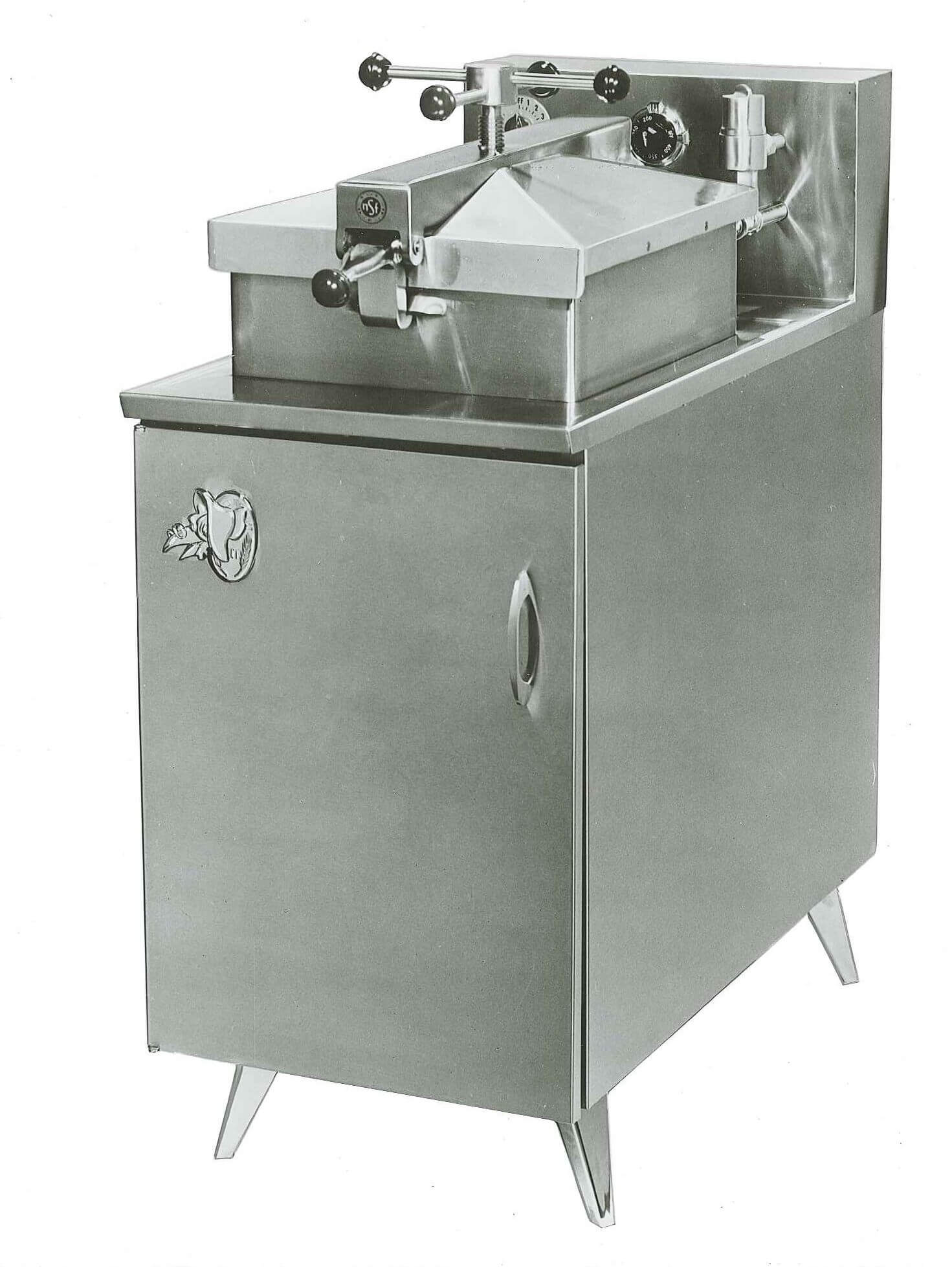

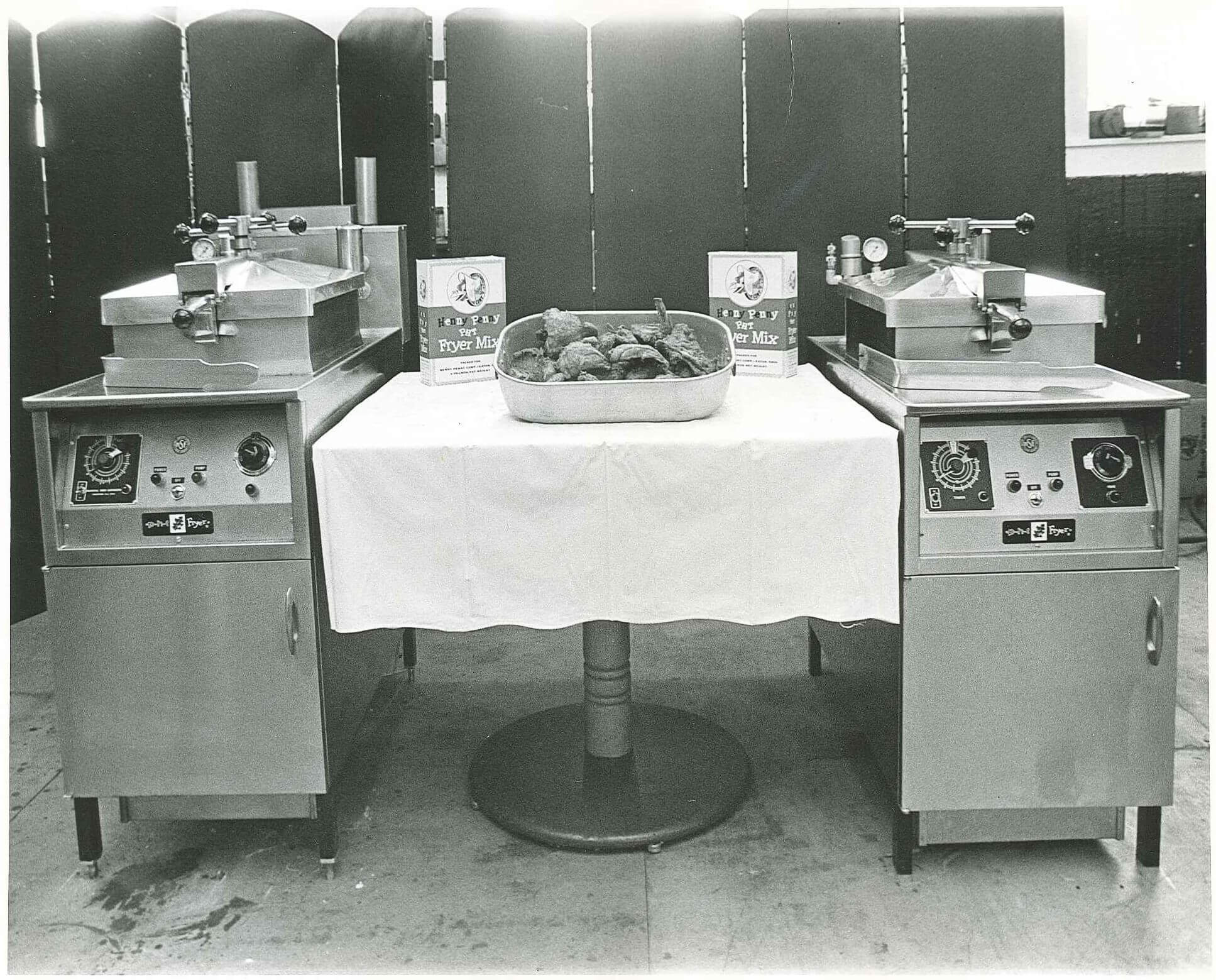

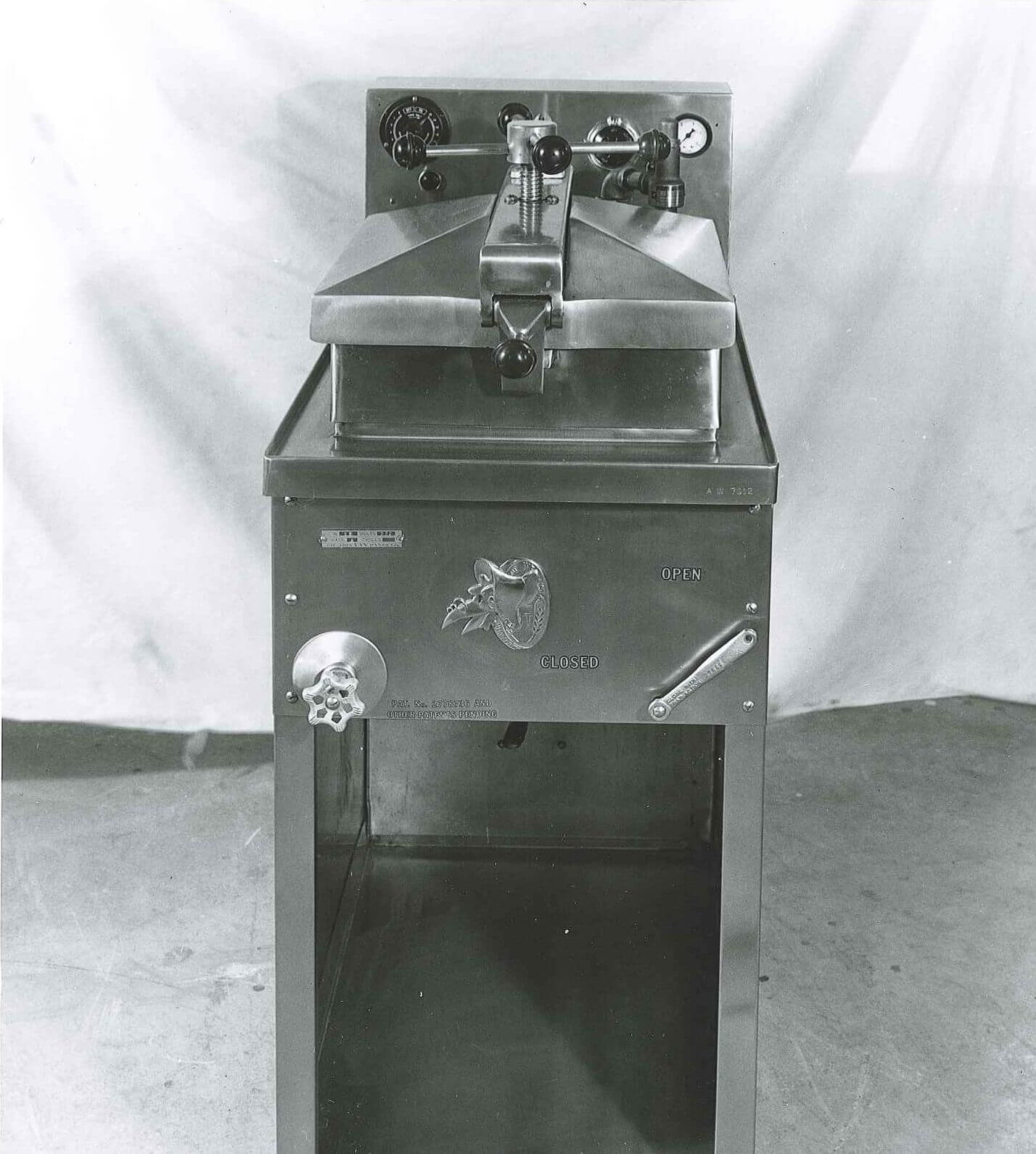

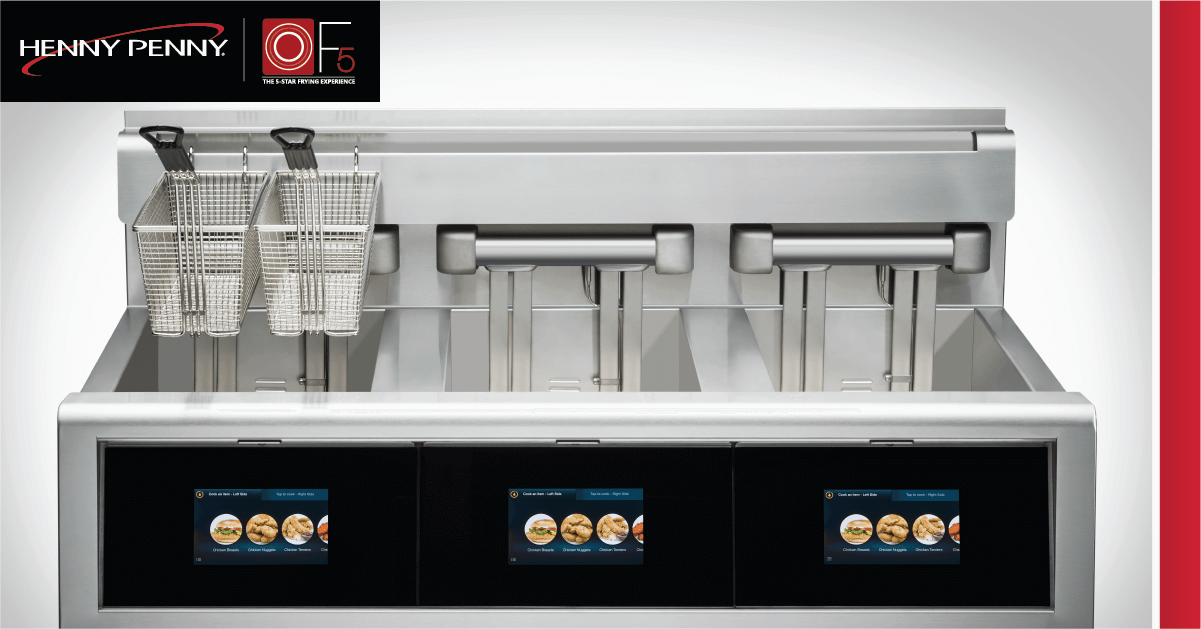

Henny Penny fryers start saving you money the second you turn them on!

Calculate the money you’ll save on oil by using a Henny Penny fryer with the Fryer Oil Calculator.